Cutting-Edge NH3 Application Equipment

Free Estimates | Designed and Built in the USA | Competitive Pricing

Free Estimates

Designed and Built in the USA

Competitive Pricing

Revolutionizing the Industry With NH3 Products

Trust ANH3 Company for modern systems and equipment to improve the efficiency and speed of anhydrous ammonia application on your farm. At ANH3 Company, we understand how important nitrogen is to your crops so we've designed the most advanced control system in the industry. Our team, which includes farmers, engineers and technicians, design and build every ANH3 product here in the United States. Call us today for a free estimate.

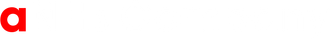

Smart Valve Technology

Improve efficiency with our smart valve manifolds that increase application speed and maintain excellent row to row efficiency without the need for extra filters.

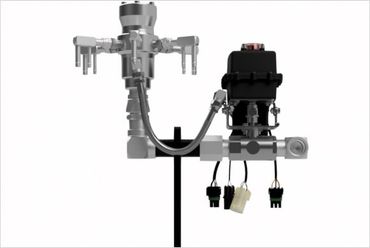

Heat Exchanger Systems

Our ANH3 heat exchanger systems are designed specifically as a low-cost cooling option for our smart valve manifolds. Call us today to learn more!

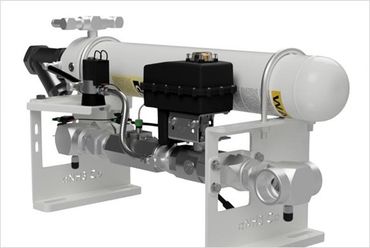

Super Cool Systems

Our Super Cool systems are offered in both pump and non-pump models and feature two flow capacities. You'll get maximum efficiency with minimal waste.

EquaRow Monitoring

Save time trying to find the cause of a problem with our EquaRow intelligent monitoring. Call us today to find out more about this unique system.

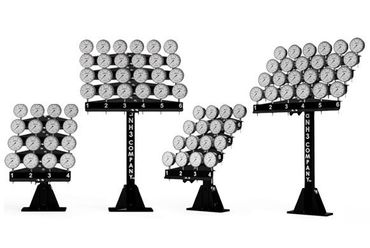

Gauge Tree Row Monitoring

Gauge trees are hard to beat for reliability and are the most economical way to monitor row by row application. Use our online form to request an estimate.

Contact Us

Reach out to us today to learn how our innovative application equipment and monitoring can help your operation save

time and money.

Share On: